Fortis live electric optical fiber (hangzhou) co., LTD

Security takes precedence over everything.Boosts reliability technology, and constantly improve the QCD.Improve customer satisfaction, build sustainable competitiveness.

Your company information

Hangzhou fuyang area inferior yucai street west road no. 1089

0571-23276666

In 2008,

Optical fiber preform

Our products are

Optical fiber preform is the core of manufacturing series of quartz optical fiber raw materials.The total synthesis of SFF with independent intellectual property rights technology, production of optical fiber preform become only to master the technology of enterprise in China.The technology has high production efficiency, production of optical fiber preform preform size, stable production process, low cost advantages.SFF is research and development, the various specifications, models of optical fiber preform manufacturing techniques.Especially the bending loss is not sensitive to the control of optical fiber, optical fiber preform the bending loss of an outstanding performance, is the FTTH (fiber to the home), the core of the product.Company products are optical fiber preform, g. 652 d single-mode fiber.

With data found us

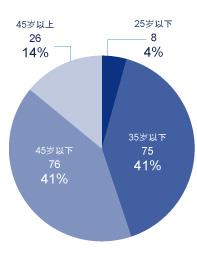

Ratio of old people

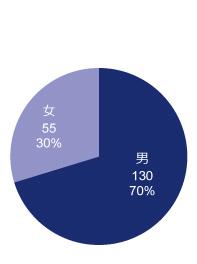

The gender ratio of number of

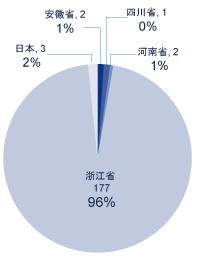

Employee hukou ratio

People

The general manager

Zhuo shan mountain

Since 1992, after the induction, has been engaged in the production of optical fiber technology, production management, development and factory operation related work.In the meantime, also involved in overseas projects such as the new optical fiber factory factory, after widely in optical fiber manufacturing related job, in July 2019 and became the general manager of SFF.Although there are a lot of not used to, but I will be on the basis of my many years of experience, coordinate with local Chinese staff to construct the security and stability of base plate, contribute to the development of Chinese society.

Our company production, is essential for the modern information society indispensable optical fiber this product.My job is to make the SFF to achieve further development at the same time, make every employee feel the value of work, to create a safe and easy to work in the workplace environment.

Contribute to the world, making all the required products of pride and self growth was achieved by work.We manufacture products that support urban infrastructure is the optical fiber products, is for the world and make contribution to the regional development, the improvement of people's living level.In addition, through the play to their maximum capacity, solve problems, so as to realize the further growth of individuals.

The experience of life experience in the company and learned is that don't give up no matter how the face of difficulties and to attach importance to the scene.Work for a long time, will face all kinds of problems.Want to give up several times, but all adhere to keep thinking about how to solve it, and inform the current state of the surrounding related personnel, eventually one day came up with a good solution, or around the person who can help me.Before, of course, problem solving, also encountered failure, but I think after failure so as to solve the problem, will become a successful experience, and can make people more confident.In addition, we provide fiber, its production is smoothly with the site.Although I long engaged in the production technology of related work, but in the face of a variety of topics, are all will solve with the operator of the field, so I think whether in what position, should remember must stand in the Angle of the field to think and act.

Is obtained to family and friends proud before work and made many new friends through work.Manufacture of optical fiber is since I entered the sumitomo electric when they want to work, so I thank you very much for company give me chance, this could have been engaged in the work and able to work in the the benefit of the world, proud before your family and friends.In addition, through the work, not only in Japan, also can make many foreign friends, I feel very happy.

Sumitomo electric has carried out a variety of business all over the world.We manufacture optical fiber is also one of these, but our product basic is hidden in the finished product, not directly.Because of this, we all staff in order to be full of confidence to provide you with better products, strive to every day.

The section chief

Mr. Hu

2007 has been engaged in optical fiber manufacturing jobs, in 2017 to join the SFF, later became the qa section chief, as usual, and you work together to strive toward a common goal.

Main work with qa department as a whole is given priority to, involved about management and supervision, the implementation of ISO9001;Product testing;Repair and maintenance of measuring equipment;Corresponding to customer complaints, complaints;And so on.

Ensure that every products are delivered to the customer hands of customer satisfaction, this is the biggest value of quality control.

If just to finish your work and work, so a few years later, you may be the ordinary employees, without any change.If think of yourself as the client, to look at your work, from the view of life after so many years, you may be a manager, even the entrepreneurs.

Sumitomo electric is inserted, which is the most satisfying a bit?

I believe that the earth people shopping concept is the same, you can buy the most satisfactory products;So, each delivery to your products, I will give myself as a buy products.

Assistant secretary

Wen-jun zhu

Everybody is good!When I from March 2010 from fortis seconded to SFF.Our department in order to "ensure safety, improve the quality and technology, reduce costs" as the objective, while around this theme, lead department staff to "wuxi, sincere cooperation, positive thinking, by heart" requirements, to finish the work.

To assist the minister to organize and supervise department staff completely fulfill the department duties within the scope of each work mission;Department annual work plan, career planning and organization to carry out the quality and cost management activity, corresponding improving measures;Assist minister on-site production, safety system of the drafting, examination, supervision, control and implementation, to ensure production safety, put an end to major safety accidents, to assist the minister guide to improve the quality, cost reduction activities.

In daily work, aiming at the plans of company;Solidarity and cooperation with all departments to ensure safety, reduce production cost, improve product quality and technical ability.

In daily "PDCA" for the working method, can successfully accomplish the work.B. to work with the attitude of "safe, reliable and progressive" to solve the problem.

I can become a member of the sumitomo electric group is a great pleasure.Sumitomo electric集团非常重视安全和环境等与生命休戚相关的问题,同时只要您努力工作,公司就会给你惊喜的收获。

Take the customer as this, with high quality products, competitive price, accurate delivery time to meet the customer's wish.

The section chief assistant

LiFeng

Everybody is good!I am LiFeng, engaged in electrical industry for 20 years, the SFF work for 12 years.Now the equipment engineering department as a section chief assistant and security supervisor position.

Improvement and maintenance of workshop equipment.Preserve the overall work plan as a whole management.

I still remember in 2009 interview last question: was the interview right section chief asked me: what kind of person you want to be a?My answer is: through their own efforts, become a respected person!

Work will encounter many difficulties, sometimes have to give up the idea of, but for the sake of his family, there will be hold on faith, meet with difficulties, insist on, insist on, hold on, way better than more difficult!

Met a lot of people and had many friends.

Fuyang is the home of the triple dongwu tundadi, welcome everybody to fuyang travel!

The Staff

Zhang Luyi

Has entered the company in August 2018, in March 2019, transferred to the administrative department for PMC and translation work.

As a administrative management department of translation, the translation of some daily work.PMC department of purchasing work at the same time.

Through continuous learning accumulation of knowledge, improve themselves, discovering their good at or interested in the field, in the struggle and solve the problem in the process of making their every bit of growth.

Some difficulties can't collapse, more fell more brave, adjust the mentality, perseverance, to be successful.

Met a group of partners give me help in work and life.

Securitization, just began to work, there are many don't understand.Please forgive me in the future, more business.

Team leader

Hu Xuelan

Since March 1, 2010 workers to SFF, it has been seven and a half years of time.Now work in the class b test shift supervisor.

Detection of shift supervisor.

From a team standpoint, through team work together to create a happy working atmosphere, improve team's enthusiasm, realize the goal of team work, thus promoting the value of team work, more can make the team have a common enterprise.From a personal point of view, is the growth management experience.

In team work and study, from the previous goal, organization, discipline, management system is not clear, the enterprise culture is weak, arbitrary processing problems, communication ability and the lack of safety consciousness.To so far, our team has a qualitative change, rich work experience, job specifications, have the consciousness of team, and to bring into full play the enthusiasm of the team, to happy work attitude towards the goal to perfect the department together.

Institutionalized management make people full of sense of trust, a sense of security.Corporate culture, all kinds of related working experience in training courses.Developing prospects for everybody.

Put an end to all the unqualified is the basic requirement of quality assurance.

operators

Shao Jun

I'm from hangzhou, zhejiang province, on the SFF work for 9 years, engaged in fiber drawing group work, have 9 years experience in optical fiber production operation technology.

Fiber drawing work

The communications infrastructure and medicine out of a force

Began as a drawing operators willing to senior teacher learning process, the accumulation of every little bit of wire drawing process, familiar with slowly understanding of wire drawing equipment, work need to be careful, patience and sense of responsibility, through their own efforts to improve their skills, to better grasp the operation experience and related problems based on the summary and make countermeasure, also get the recognition of leaders and colleagues, and promoted to a drawing the group leader, in the work to the implicit cooperation among team members, through their own management methods can better finish the work.

For the company's working environment is my most happy thing.In the production of optical fiber higher requirements to the environment.Field of health, items of an education is very important for the security of the employees.Safety first, quality is our work standards at the same time.The stand or fall of work environment also need each staff to maintain and keep, I will set a good example to lead good team members.

Good working environment, advanced production technology, strict quality control, we strive for what we produce every product with excellent quality.

Stories

Found at the scene to solve problems in the present

SFF to strengthen cost savings as a basis for further development

Fortis live electric optical fiber (hangzhou) co., LTD. (hereinafter referred to as SFF) in the process of implementation of efficient production and quality management, company management pays attention to the saving of the cost of production.In today's market, especially to pay mode to hub environment, for most enterprises and SFF, price has become the market transparency of operation, while corporate profits depend on high and low comprehensive cost, and the leading comprehensive cost is a basic factor of process waste.In addition to the enterprise in the operation process of waste, and what are the hidden costs can be saved, all became a matter of company managers daily concerns.

SFF in unloading process for products out, and constantly improve the packaging and freight transportation mode to achieve safety and cost savings.After repeated comparison, discovered that the distribution of efficiency is to reduce logistics cost effective way to select the best means of transport, goods in transit to shorten the time, from the original single air, to the land, as far as possible to reduce delivery times, at the same time in order to improve the cubed out and reasonable arrangements to plan, thereby reducing distribution costs.

SFF managers pointed out that, from set out actually, strengthen the cost management consciousness of the employees, to strengthen cost accounting, reduce the cost of work gradually extended to the company's various positions;To strengthen the construction of the proposal by the implementation of proposals to achieve cost savings, and form a normalized construction, has formed within the company long-term development "strategic cost consciousness", provided a basis for further development.(Wang Xiaoye)

More measures to boost growth and stable cost reduction benefits

SFF to strengthen cost savings as a basis for further development

Fortis live electric optical fiber (hangzhou) co., LTD. (hereinafter referred to as SFF) in the process of implementation of efficient production and quality management, company management pays attention to the saving of the cost of production.In today's market, especially to pay mode to hub environment, for most enterprises and SFF, price has become the market transparency of operation, while corporate profits depend on high and low comprehensive cost, and the leading comprehensive cost is a basic factor of process waste.In addition to the enterprise in the operation process of waste, and what are the hidden costs can be saved, all became a matter of company managers daily concerns.

SFF in unloading process for products out, and constantly improve the packaging and freight transportation mode to achieve safety and cost savings.After repeated comparison, discovered that the distribution of efficiency is to reduce logistics cost effective way to select the best means of transport, goods in transit to shorten the time, from the original single air, to the land, as far as possible to reduce delivery times, at the same time in order to improve the cubed out and reasonable arrangements to plan, thereby reducing distribution costs.

SFF managers pointed out that, from set out actually, strengthen the cost management consciousness of the employees, to strengthen cost accounting, reduce the cost of work gradually extended to the company's various positions;To strengthen the construction of the proposal by the implementation of proposals to achieve cost savings, and form a normalized construction, has formed within the company long-term development "strategic cost consciousness", provided a basis for further development.(Wang Xiaoye)

Strengthen the internal management to improve the quality of the company

5 s + 1 SFF within the company management system

In order to better promote the scene management, fortis live electric optical fiber (hangzhou) co., LTD. (hereinafter referred to as SFF) in July 2012 with the introduction of 5 s + 1 (sorting, reorganization, cleaning, cleaning, quality + security) the scene management, the production workshop to implement 5 s + 1 on duty of the whole system, from the most basic work environment, work habits and behavior, in the process of execution, and constantly improve and supplement, formed a set of guiding, plan, check and rectification of the continuous improvement of work process, improve the site management assessment method, the 5 s + 1 management activities as the basis of enterprise management work and important work, constantly to the 5 s + 1 site management goes ahead, the quality of employees.

Per shift to a regular patrol, 5 s + 1 bear convened by the tour leader regularly patrol staff participation, staffed by a team of log book with red armbands, on duty personnel should be red to wear in the left arm, every tour of the unqualified item should be at the next travels to follow up and review.Daily production of regular and irregular inspections, inspections of not less than 4 times per class.Patrol leader is to assist the team leader on duty management of class, in the work process of 5 s + 1, strengthen the maintenance of class, this process in the production of site management.And have the power to class or process within any violations, dissuade, education and examination of violations, get twice the result with half the effort effect on the daily management work, has received the good effect.

This system has got the attention of the company managers, and points out that, to further strengthen job training as the main content of the basic skills training, improve the population quality and the working ability of the enterprise staff, enhances the vitality of the enterprise;Through 5 s + 1 activities, with the site specification, reasonable and meticulous management and regulating the behavior of individual daily work to improve people's quality, improve people's quality, for each member to create a good working environment and harmonious harmonious working atmosphere;Hope that through company personnel involved in the inspection and management of 5 s + 1, better able to enhance the level of management, and can discover more outstanding management talent.(Wang Xiaoye)