The Launch of Three Newly Developed Cutting Tools to Achieve High Efficiency Machining

To reduce lead times and the cost of producing machine parts, there is a growing need to increase the manufacturing efficiency and extend the tool life of cutting tools. This section introduces three new cutting tool products that meet these needs and achieve high efficiency manufacturing.

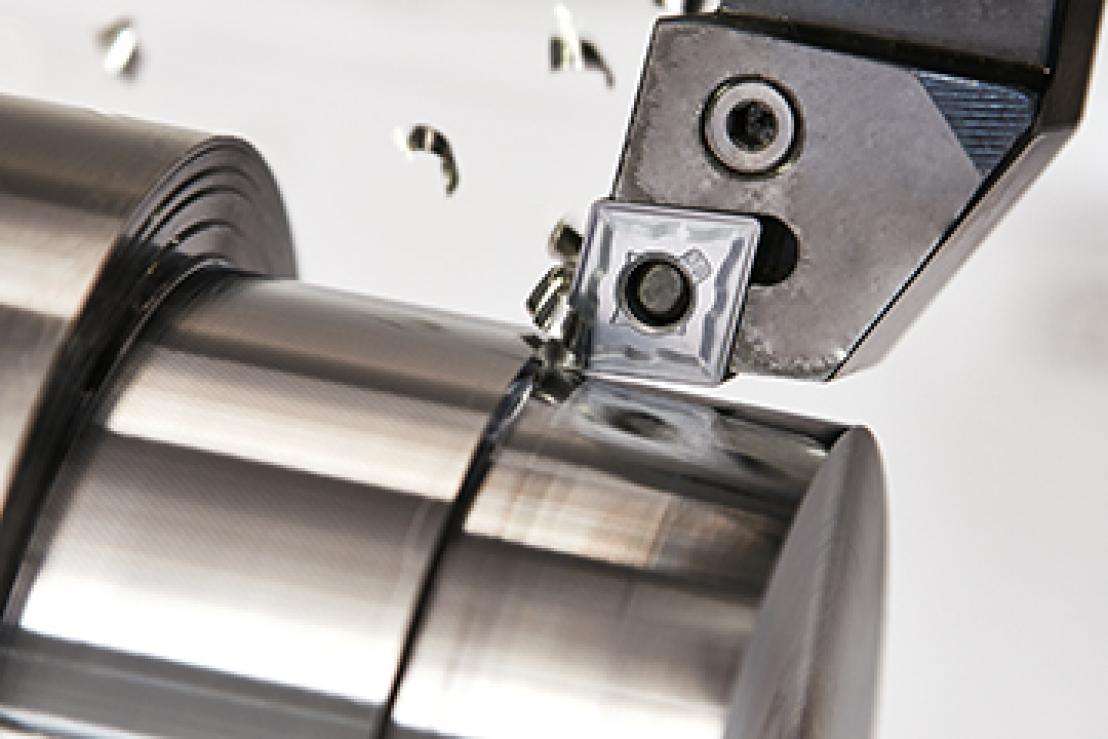

1. AC8020P New coated grade for steel turning

This insert grade is ideal for high-efficiency steel turning in the production of parts used in the automotive, heavy electric equipment, steel, and construction industries.

Chipping resistance has been improved by more than 2.5 times that of conventional products, so as to achieve excellent stability and longer tool life in the high-efficiency machining of medium to high carbon steel.

2. AC5005S New coated grade for turning of difficult-to-cut materials

This insert grade is ideal for machining difficult-to-cut materials, such as Ni (nickel) base alloys, Co (cobalt) base alloys, and Ti (titanium) alloys, which are often used in the aircraft and medical industries due to its superb heat resistance and corrosion resistance. With 1.5 times higher efficiency in machining difficult-to-cut materials than conventional grades, tool change frequency and tool consumption are reduced, resulting in lower tool costs.

3. SEC-Sumi Dual Mill™ DMSW Type high-feed roughing cutters

High-feed milling cutters for high-efficiency roughing that meets the various machining needs of the automotive, aerospace, ship building, industrial machinery and die-mold sectors.

A composite arc-shaped cutting edge design with multiple connecting arcs, made possible by advanced insert molding technology, enables high-efficiency machining at ultra-high feed rates and large cutting depths, and achieving excellent surface roughness. Even when machining with long tool overhang, stable machining is possible without chattering.